|

|

CONTROL SYSTEM OF HIGH PRESSURE PARAOSCILLATORS

“RVSA”, Ltd factory develops a universal control system Boiler units of drum-type type. The system is builted with use of the equipment and Devices of manufacture of firms "Siemens", “АBВ”, “JUMO”, “Moeller”, resources which allow to solve almost all problems connected with automation, protection and the signalling system of a process of a steam production.

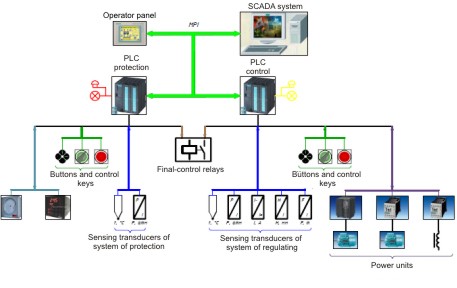

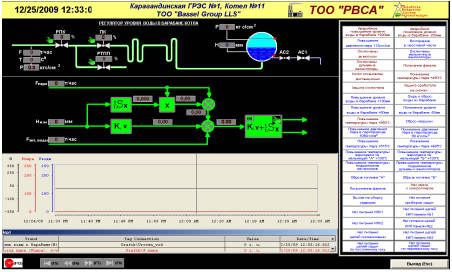

Picture No1 Two control units (regulating and protection) accept discrete and continuous signals from sensing transducers and secondary devices of measures. On the gained Informations control units perform logic and mathematical operations of machining the accepted information on the put in pawn algorithms managing directors also give out and signalling commands on power units and visualisation panels. Visualisation of processes is provided by means of two panels of operators (LCD the monitor and TR- 177V). Installation of the third panel separately for system is possible protection automatics. On the monitor it is represented scheme with animation on which it is possible to trace work of mechanisms of a copper, the basic technological parametres and as are inferred text messages precautionary and the fault signalling. Representations take places in several windows:

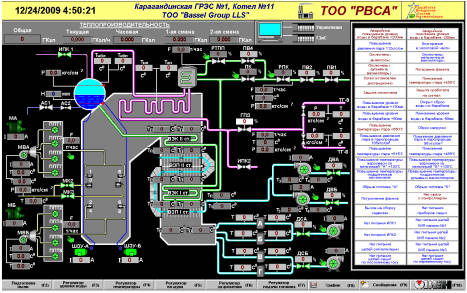

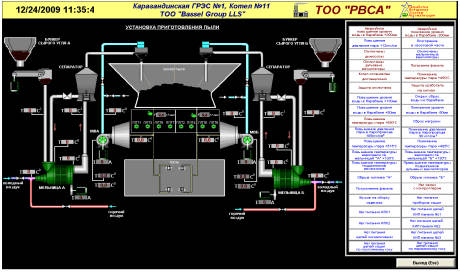

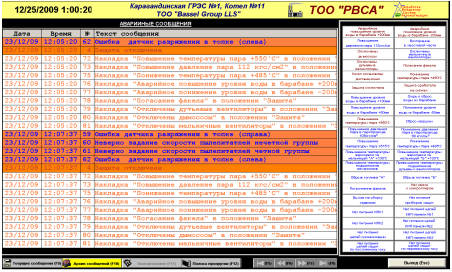

Picture No2. The copper circuit design  Picture No3. The circuit design of system of preparation of a dust System of visualisation besides representation of key parametres arriving directly from sensing transducers of physical quantities such as: pressure, temperature, level, the charge, rule of final control elements and токовые loadings electric motors, makes as calculation of thermal productivity of a copper, fuel rate and a specific fuel rate on 1 Gcal. For calculation of thermal productivity of a copper calculation formulas are used antalpii waters and pair, resulted in recommendations MI 2412-97 and MI 2451-98 VNIIM of D.I.Mendeleyev, accuracy of calculation is not worse than 0,5 %. Calculation of the expense of fuel (A coal dust) it is made on speed of rotation and quantity of the working feeders according to their adjusting characteristics. On scheme in the form of pictogrammes the operating mode of the executive is displayed The mechanism - manual or automatic. On all screens messages are on the right side deduced. Again appeared message blinks, while it not blinker. A signal on which has occurred emergency stop, it is marked by a shone point in the field of the message. The disconnected protection is marked grey field of the message, corresponding signal. Automatics of protection provides a copper automatic stop in critical modes when this or that parametre exceeds admissible size on to conditions of safety of process, or the developed situation can lead to destruction of the equipment or ecological accident. Work of emergency system is accompanied by the sound and light alarm system, a conclusion of text messages to the basic and duplicating panels of operators. The system fixes the original cause which has caused an emergency. All events are fixed in a window of messages in chronometric sequence with the direction of a concrete time of their origination, receipting and disappearrance. Algorithms of work automatics are realised in the programmed controller Simatic S7, specially intended for this purpose, and having a food from two independent sources (~220V and =220V) with UPS. The control unit противоаварийной automatics can be completed, instead of luminous panels, own display for representation of messages. The analysis of a condition of a copper is defined on discrete signals of achievement of marginal levels by the copper operation factors, arriving from secondary devices by which the copper is equipped. In addition signals of marginal levels arrive from the regulating control unit Simatic S7 300, which processes signals of analogue sensing transducers, than it is provided duplicating of an alarm. Regulating of technological parametres is provided with the program of the second controller.

The regulators affecting power units of directing apparatuses and regulating valves, have knot of compensation of gaps of the mechanism of the drive. Besides, the drive of valves and power units can be completed with the frequency drive that will allow to provide exact and smooth regulating of parametres, to lower electric and mechanical dynamic loads on the drive. Frequency are controlled the drive (FCD) it is possible to operate on a network and to gain the information on speed and loadings. For locked latches FCD will allow to retard speed at the approach to the closed rule and on the moment (FCD gives out a moment signal) to disconnect the drive (reliable and safety closing). The drive with FCD are less subject to breakages in a mechanical part of the mechanism and propellers fail (highly reliable and a scram protection) less often. Thus it is possible to represent more than the information on work of power units. The bumpless transfer from hand control on an automatic regime and back is provided. Regulating зumpings out and air supplies with dual system of flue-gas pumps and ventilating fans provides uniform loading of propellers (a regulator division of loadings). Besides, at emergency switching-off of one of propellers, second it is automatically inferred on the maximum productivity (the greatest possible opening of the directing apparatus on a condition current loadings) and then is connected to regulator, the system defines necessity of automatic decrease in loading of a copper. Was possiblly installation FCD for flue-gas pumps and ventilating fans that provides regulating without use of directing apparatuses (very much a cow-hitch), smooth dispersal without dynamic loads, decrease in a slump of voltage and starting currents at start-up, that positively affects durability of electric motors. Regulating by means of turns reduces loadings on the mechanism and increases service life of flue-gas pumps and ventilating fans. In addition to stated all above the current consumption decreases and raises COS.

For air regulator the system of extreme regulating with an automatic search of an operating point of a relationship air-fuel, providing the minimum specific fuel rate on manufacture of one Gcal heat develops. Loading of the crumber and temperature airdust mixes is controlled by change of productivity to the DOG with the frequency drive and extent of opening of gates

For each regulator there is a shield in visualisation system that allows to control quality of work and to observe changes of parametres in dynamics on time schedules. Look picture No 4.  Picture No 4. Level regulator

Picture No 5. Window of messages All operating equipment is protected from mechanical injuries and to dust penetration for what filters and leakproof cabinets are provided. Hand control bodies (buttons, keys of sampling of a regime have illumination) take places on benchboards taking into account ergonomics and convenience demands Managements. Cabinets with the switching equipment are equipped by safety keys, the signalling system and protection against loss of a phase and incorrect phasing. Partially this system has been realised in the course of repair-regenerative works on a type copper - PC 10. A copper пылеугольный, drum-type, water trumpet, with the vertical shields, consisting of the basic and prepowered drum, system of screen and connecting pipes. Productivity - 230 t/hour., workers pressure in a drum - 109 атм., gaseous steam temperature - fuel S.Szhiganie's 510 grades torch, copper configuration P-shaped. The copper is riged by 8 pulverised-coal burners. That attains accuracy of maintenance of a water level in the boiler drum in an automatic regime +/-7 mm. Accuracy of maintenance of temperature on an entry in the general collecting channel +/-100С, at an arrangement ыteam cooler before a prime of the steam superheater and without the temperature control between the first and second steps of the steam superheater because of absence of the sensing transducer, i.e. most not favorable conditions for automatic control system. |

www.rvsa.kz www.rvsa.ru

|