Control, diagnostic system and technical process control

Customer: JSC “KarCement”, Karaganda region, Aktau

Reconstruction object is grinding shop No2, cement mills No3,4.

RECONSTRUCTION OBJECT SPECIFICATION

Reconstruction object is cement grinding lines No 3,4.

Cement grinding mills of grinding shop No2 are intended for cement getting by clinker,

mineral white and slag grinding using “dry” technology. Reconstruction was carried out

with essential reducing of old system service reability.

It often led to accidents, lenghty downtimes and getting defective products.

Requirements to automation system

- reliability;

- service availability;

- process variable value backup;

- events archive;

- work monitoring.

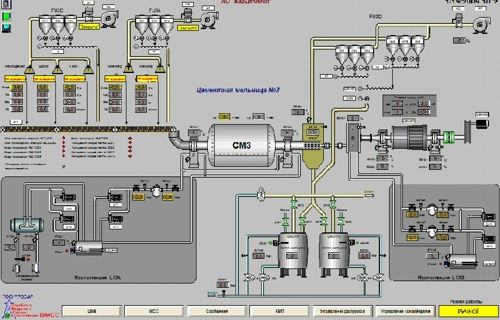

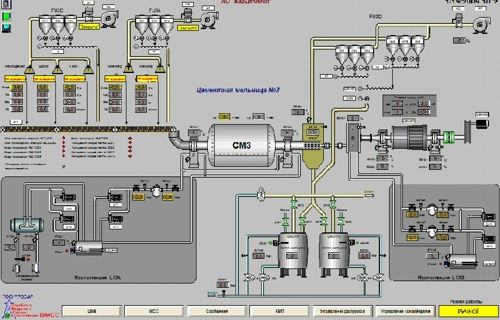

Picture №1

The system consists of following main components:

- programmable controller PLC of the firm ABB series 800, set in the main pulpit of the grinding shop;

- removed inlet/outlet module, set in the oil-station;

- removed inlet/outlet module, set indoors MCC;

- removed inlet/outlet module, set on the clinker storage;

- visualization system.

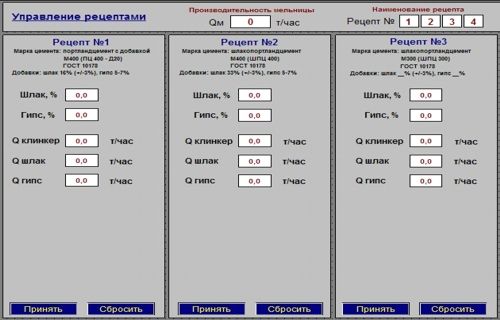

Picture №2

Visualization system of technological process is realized on the basis of PC, set on the central cement mill pulpit.

Program products are used as software:

- WinCC 6.2 basic system for

solving extensive complex tasks

of human-computer interface

from project development of

singl station to power system

with client/server architecture;

- Windows XP pro.

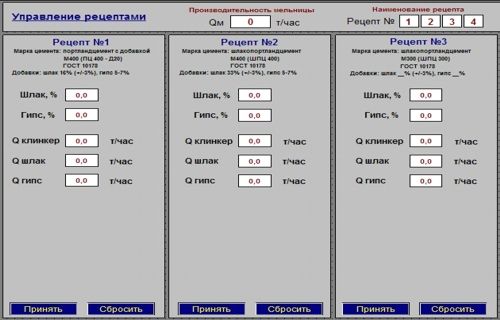

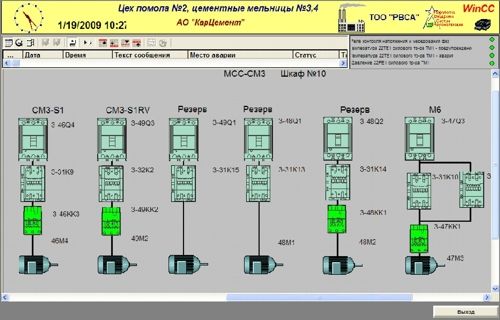

Picture №3

System functions

- safety and warning alarm

- date acquisition about technological process and equipment condition

- archiving of current data in the form of diagrams

- technological parameter setting

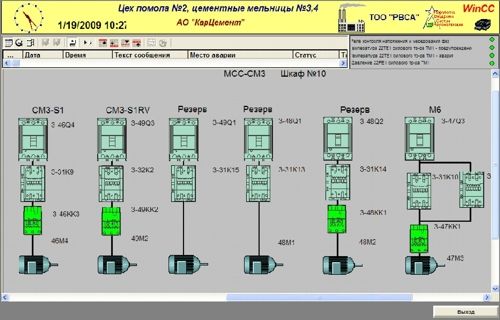

Picture №4

The connection between ABB controller and SCADA system WinCC is realised on Ethernet using OPC–Server.

OPC (OLE for Process Control) is international connection standard between components in industrial automation.

According to the technology, on the basis of Windows, created OPC supports open interface,

providing free and standardize data exchange between programmable logical controllers, control systems and

desktop apps of different producers. Any software can be installed on the OPC client, answering conforming OPC standards.

So, OPC client can be used, for exaple, for data analysis from different sources. Using individually developed OPC clients,

It can be satisfied any requirements at the highest level.

Project implementation period

Project implementation period is 12 months, commissioning is 2009