|

|

Electric drive modernization (main movement of the table) spiral planer model 7110

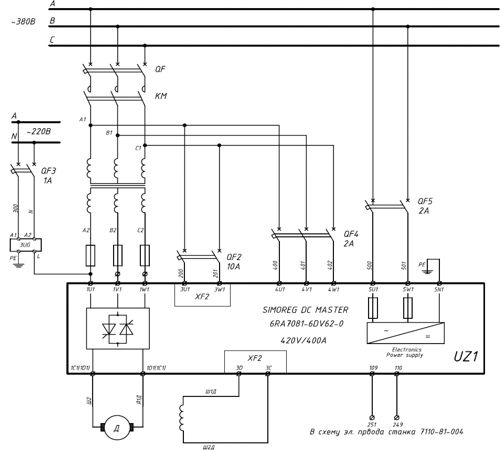

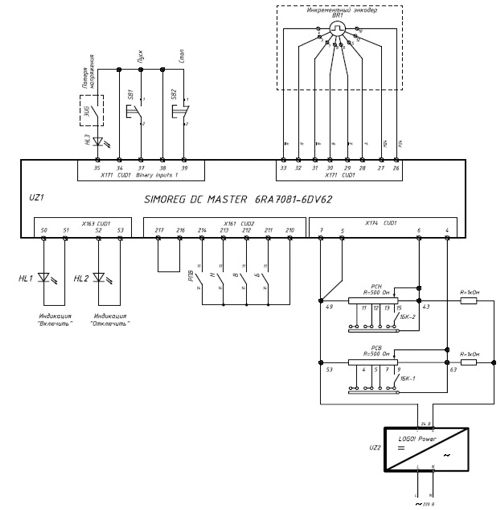

Customer: “Korporaciya Kazakhmys”, Ltd. (Casting and mechanical plant), Karaganda Reconstruction object:: spiral planer modal 7110 Table reciprocaring movement with processing detail at the required speed is carried out by two-range transmission and regulated reverse DC electric drive according to the system “variable-voltage system” with a rotating amplifier of crossed field, feeding generator field-magnet coil. . For setting of required cutting speed it was installed two high-precision variable resistors: РСВ and РСН. Necessary speed of combustion stroke is installed by speed set unit РСВ, and backstroke speed is installed by set unit РСН. Sliding contacts of the high-precision variable resistors РСВ and РСН provide necessary speed diagram, it depends on the table position.  Picture No1 Assembly view of the machine model 7110 Converters SIMOREG DC MASTER of series 6RA70 are fully digital rugged converters with powering from three-phase network and service for feeding of an anchor and DC motor exciting coil with regulated drive. Packaged construction SIMOREG DC MASTER provides high operating efficiency, thanks to easement of access to each component. Electronics baskit contains a control baseplate, also additional plates. Using of the converter with its optional plates together, i.e. S00, allowed very minimizing relay contact mill control circuit, it increased reliability of the system work, changed morally and physically out-dated switching equipment. There is a drive force circuit on the picture No2, and there is its control diagram on the picture No3.  Picture No2 An electric drive force circuit of the mill model 7110  Picture No3 Electric drive control circuit for the mill model 7110 It is worthwhile to say that during the main electric drive modernization of the machibe it was used an optical incremental removal transducer for the determination of the table position. It gave the possibility to provide soft characteristics of table acceleration and breaking during its reciprocating movement in clearly set working zone, which will be able to change easily depending on size of the processed part if it is necessary. In this case it is possible to refuse from sliding contacts РСВ and РСН. Commissioning is January, 2007 |

www.rvsa.kz www.rvsa.ru

|