Frequency-regulated drives in control system

reconstruction

During recent 10-15 years AC regulated drives with autonomous AC invertors or

voltage essentially threw out DC drives in area of technological process automation.

When pulse width frequency converters appeared instead of forced-commutated

inverters at the market, popularity of frequency-regulated drive increased sharply.

Nowadays produced converters include power range from tens of voltage-ampere to

hundreds of megavoltampere and voltage from 100 v to 10 kv.

Modern frequency-regulated drive differs by high reliability, efficiency, and

according to its static and dynamic characteristics it is little different from DC drive, and

sometimes overcomes it as follows:

- Used AC engines in frequency-regulated drives

are more reliable than DC drives and simpler in

operation. They are environment-proof and can

work in heavy conditions.

- It is not required rotation velocity sensors in

many supplements (speed noncompensated system).

- There are very hardening characteristics when synchronous motors are used.

- Protection of the motor, the converter and machining facility is more

reliable and more effective, thanks to the pulse-duration modulation

principle (modulation frequency from 1 khz to 20 khz) in combination with

microprocessor protection system.

Nowadays used frequency converters with voltage or current autonomous

inverters have properties as follows:

- Digital microprocessor system jointly with

vector control strategy permits getting good drive

characteristics even at low frequencies, providing

maintenance motor torque at zero turns in some

cases.

- Good energy values:

- good COS,

- a low level of the highest harmonics,

- high efficiency.

- Output current configuration is close to sine

curve. It allows using all-purpose electric drives

without additional filters and isolation

enhancement under certain conditions.

- Braking energy recuperability in feeding net (converters with the controlled

rectifier special circuit or with the current inverter).

- Automatic connection of converter to rotating motor, so called “immediate

grab” mode.

- Soft acceleration and breaking reduce dynamic loads on the mechanical

parts of the unit and feeding net.

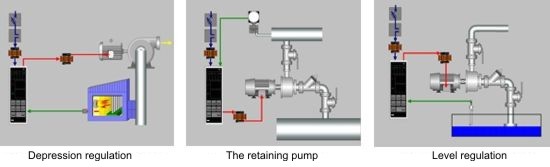

Picture No1

Application area of frequency-regulated drive is extensive and envelops different

sectors of the national economy. They are used for various technological units, singular

devices machines and test desks.

In attached reference list there are objects, where the frequency-regulated drives work successfully,

implemented by “RVSA”, Ltd.

Here are some examples of frequency-regulated drive application.

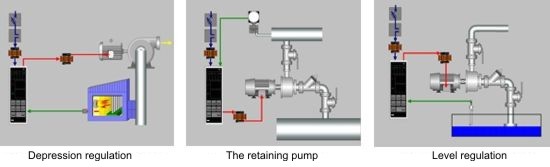

Production, pump head and ventilators, material level in volume operation

Picture No2

Constrained parameters are changed or supported by motor speed control.

In these frequency-regulated drive applications it is reached maximum electric power economy,

in some cases it reches 50 per cent against traditional regulating system with regulating valves and guide wheels using.

In the cases of level regulation it is often necessary to make repeated starts and stops (regulation on the principle of ON/OFF),

frequence-regulated drive permits to balance pump production with product arrival, providing regulation continuity.

Soft acceleration and work at rate speed lower nomenal one reduces machinery wear and tear,

eliminates line ruptures because of hydraulic hammers and overpreassure.

Switching off and on of electric power circuits is carried out in no-current conditions;

it prolongs operation time of power-operated switch apparatus. Generally it’s not necessary additional

instruments and automation equipment in particular technological parameter regulating devices, as there are built-in digital

PID-controllers in converters.

Application area:

- water-pumping stations,

- slurry pumps,

- forced-draught and vacuum fans,

- fume exhausters,

- charging pumps of Power station,

- main pump units of oil and gas pipe lines,

- vantilation facilities,

- compressor units.

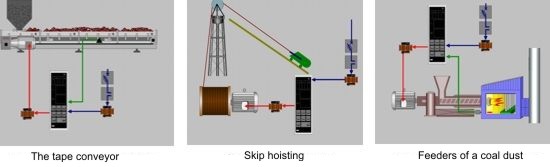

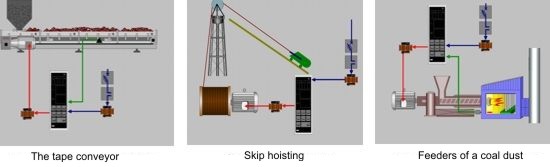

Hoisting machines, conveyers, dosemeters, feed mechanisms, skip hoist

loaders, transfer mechanisms

Picture No3

- Frequency-regulated drive using in hoisting machines (overhead travelling and

gantry cranes, skip hoistings) permits to reach soft start conveying speed

stability. Control circuit is very simple, it is reduced start-control devices quantity,

cable production requirements become less, it is not necessary start-control

resistors. It is reached energy economy because there is no dissipation of

regulating energy on resistors, and it’s possible motional energy recuperation in

convertors and braking energy in network. Stopping accuracy or point-to-point

operation is very high, thanks to wide range of speed regulation and inbuilt

dynamic braking action by DC.

- Frequency-regulated drive using in band conveyor druve provides soft start and

acceleration, we have possibility of production control. Using of two-zoned speed

regulation system (a motor works on the frequencies more than 50 hertz) allows

using motor with lower rotations and of course with underestimated power, to

reduce energy consumption and current load on the network. Low power

equipment costs cheaper. Working in the second zone, the torque on the motor

shaft is reducing but it doesn’t influence on the normal work, in this case required

operating torque is generally lower (a blank cartridge, low weighload on the belt).

- Power unit armory by frequency-regulated drive of coal or dust feeder very

improves burning process control. Converters are conformed to combustion

controllers through inbuilt digital motor pot resistor or they carry out temperature,

pressure control directly, using inbuilt digital PID regulator. Control system on the

basis of frequence-regulated drive is more compact, reliable in work and contains

less eliments.

- Metal cutter drives, sheet metal work line is also provided with frequency-regulated drives.

Operating experience has shown reliable work, strategy the best way

of implementation with the friquency-regulated drive.

"designed-bought-installed-adjusted-closed and forgotten!!!"

SIEMENS Converters, for example, have the following options:

- In-built network interfaces

- Additional programmable functions of signal conversion.

It allows combining of several drives in one control system, without any

complecated external relay-contact schemes and commutation connections”.

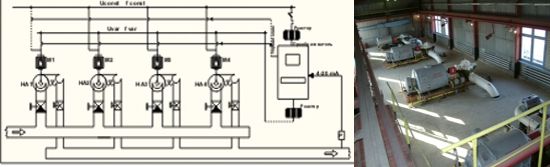

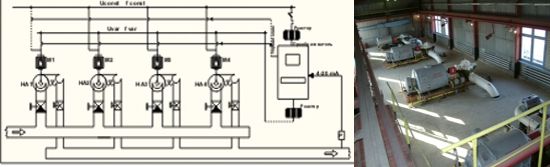

Pumping stations

As a rule, pumping stations are provided with two, three, four and more pumps,

working parallel on the general controller and sequentially on one pipe. In these cases

for maintaining of set consumption and pressure at outlet of the station, it is enough to

have one pump in the regulating mode for the station, and other pumps are switched on

in the full acceptable production. «Multi Pump» mode is used to operate such kind of

system, its operating principle is shown at the picture below.

Picture No4

At the beginning one pump is put into operation by frequency-regulated drive, if

its production isn’t enough, it means as follows:

- converter output voltage is getting synchronized with network voltage in terms of frequency and phase.

- also stress ranges are aligned,

- mottor is disconnected from frequency-regulated drive,

- bypass switch is switched on,

- motor begins to work from net,

- the next motor is connected to frequency-regulated drive,

- frequency-regulated drive is switched on and brings a motor to engine operating speed,

- engine regulation is carried out with the help of the unit which is connected to frequency-regulated drive aggregate,

- further process can continue by connecting the following aggregates,

- at the constrained parameter overriding, cutoff in reverse order happens or the

first coming into operation motor is disconnected off.

Such circuit saves several converters at marginal increase of costs on switching

devices. There are soft acceleration advantages of pump drives, as each motor at

the moment of switching on is connected to converter.

It’s not always required rotation frequency regulating process, it’s only enough to

provide soft start and soft stop. These units are turbocompressors, some airing plants,

conveyors, calenders, devices with the big rotating mass, devices which don’t permit big

dynamic force. In this case it’s better to use units known as soft start units, where soft

start can be reached at the expense of voltage regulation on the motor stator. Also it’s

possible using of motor group operation mode from one unit with successive start and

the next motor shifting transfer to network. Soft start equipment is cheaper than

equipment for the frequency-regulated drive. It has wide power and voltage (till 10 kv)

range. Control system is microprocessing; protections are varied and protect a motor

and equipment reliably.