|

|

Reconstruction of main drive control system at finishing group, reserving of pinch devices of finishing group at HRM 1700

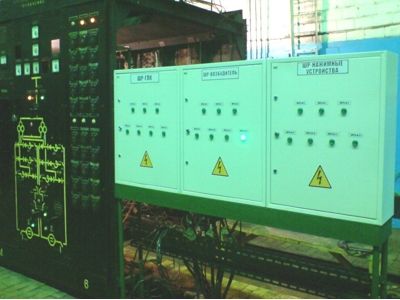

Customer: JSC “Arcelor Mittal Temirtau” Reconstruction object: electric drives equipment at HRM-1 1700гп Reserve machine complex include the following devices:

Picture №1

Picture №2 For service convenience it was developed diagnostics and control system on the basis of operator’s panel МP277. The panel is destined for displaying of drive electric equipment condition. Developed graphic OP structure allows a dispatcher to control working modes, to watch and react on all emergency and pre-emergency conditions of electric drives at stand. Also in diagnostics system it is carried out permanent archiving of parameters as follows:

During connector connection, reserve converter control system receives binary code, corresponding to connected stand number. Then comparison of three signals happens: stand code, received from the connector; stand code from the SAUS system and the signal from the power contact-breakers. Availability of these signals permits to work reserve TP, in this case availability indicator to the reserve stand work is lighted up on the cabinet SHR-GPK. During the code recieving of the stand, in the reserve converter GPK control system with the help of multiplex switchs and the function «DataSet» required parameter adjustment happens as follows:

Picture №3 To simplify the work of stands control relay circuit, programmable logical controllers LOGO! 230RC are installed on each control system board (6-12), therefore LOGO takes upon itself the main control by automatic machines work of the stand motors. It is very simplifies relay control circuit configuration and provides high reliability. Also diagnostics time of emergency situation is reduced, because on LOGO it is displayed all main technological blockings, when it happens it is displayed messages with corresponding priority. Reserve control system of GPK excitation and screwdown arrangement is constructed on the principle of main drive converter reservation. |

www.rvsa.kz www.rvsa.ru

|